UR5 Robot

This collaborative robot from Universal Robots is one of the first industrial collaborative robots. Its precision and payload capacity make it a very versatile system.

Inside, it is controlled by the Polyscope graphical interface, which will be accessed via the 14″ touch panel that comes with the controller and the robot, allowing for easy programming of the robot.

Features

This robot, being a light industrial collaborative, has a multitude of applications such as parts assembly, Packing, Testing, Pick & Place and Bin Picking.

| Load | 5kg |

| Maximum range | 850mm |

| Precision | 0.03mm |

| Weight | 20,6kg |

| No. axes | 6 |

RG2 Gripper ONROBOT

This gripping system from Onrobot allows easy integration with UR robots. It has a Plug-and-Produce design, reducing set-up and manipulator changeover time.

The RG2 collaborative gripper allows customisation of the tips. Large stroke, display grip indications, force and stroke adjustment, automatic TCP calculation (in UR), automatic depth compensation (in UR) and automatic payload calculation (in UR).

These features provide the system with the necessary characteristics for packaging and palletising applications, machine maintenance, assembly and pick & place.

Robotic hand qb SoftHand.

qb SoftHand is a 1:1 scale anthropomorphic robotic hand based on soft-robotics technology. It is flexible, adaptable and able to interact with the surrounding environment while limiting the risk of injury to operators, damage to the products to be handled or damage to the robot itself.

The qb SoftHand is adaptable and can grip different objects without any change in the control action, displaying an unparalleled level of simplicity and flexibility.

Thanks to the soft material covering, the qbrobotics hand exploits the principles of synergies in a simple and intrinsically intelligent design. It ensures human-robot interaction and also adapts to grip different objects without any change in the control action.

Its flexible gripping device can grip a wide variety of objects. Single-driver actuation makes the hand plug-and-play and easy to control (a single driver requires a single control signal to close and open the entire hand).

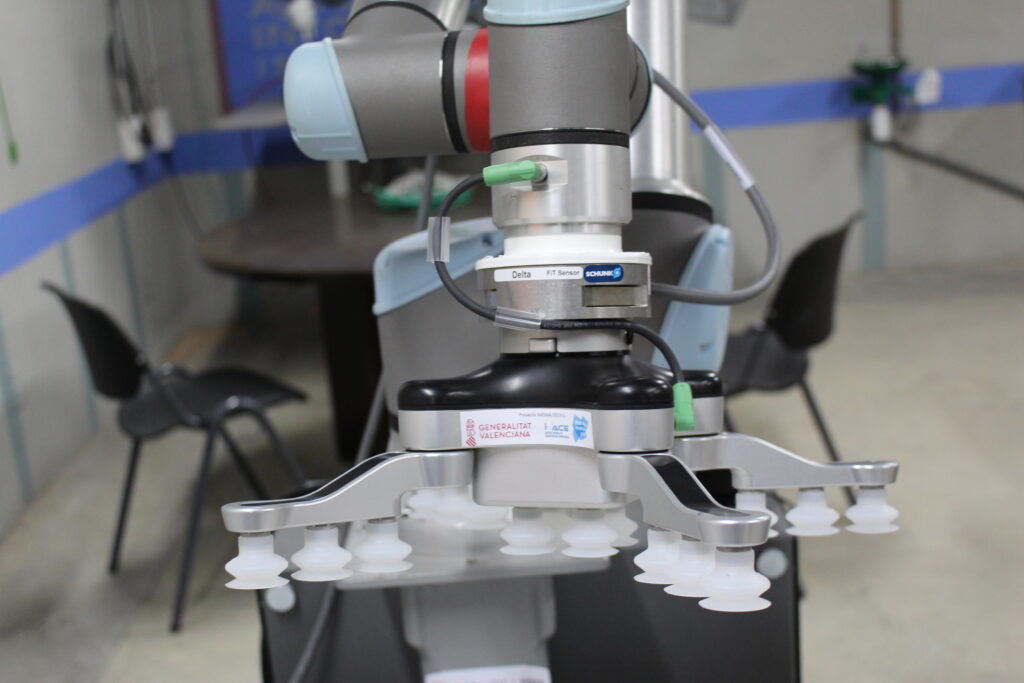

VG10 Vacuum Gripper

The VG10 gripper requires no compressor or air supply, is compact and easy to move, providing flexibility on your production line. The VG10 vacuum gripper’s flexible arm configuration and adjustable vacuum allow the VG10 to handle a wide variety of different sized objects.

The clamp comes with double grip functionality, tool changer and a variety of typical suction cups. In addition, there is a wide variety of third party suction cups available on the market.

The VG10 vacuum gripper is a Plug & Produce solution. It works straight out of the box and on your production line in less than 30 minutes.

Seamless integration with Universal Robots and compatibility with generic robot interfaces make the VG10 ideal for all types of robots. As of mid-February 2019, it also supports KUKA, Kawasaki, FANUC, Techman, Doosan, NACHI and Yaskawa robots.